WhatsApp)

WhatsApp)

Vertical Cement Mill, Vertical Mill In Cement Plant Brief Introduction Vertical cement mill is the key equipment to smash after material to be broken. Vertical mill is widely used in cement mill, silicate products, new building materials ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology 2 Introduction Around 110 years ago a Danish engineer, M. Davidsen, patented a ...

Vertical Roller Mill Production Line,gypsum Powder Mill Water slag vertical roller grinding mill machine. Water slag mill can direct water slag crushing and grinding, cement industry is now mostly by lime stone material processing to ...

Vertical Roller Mill The most important use of LUM series ultrafine vertical roller mill areas may be cement field, which will be directly applied to the cement grinding production and life, providing direct foundation for the development of ...

LUM vertical roller mill appearance makes a onetime completion of ultrafine grinding, grading and transportation into reality, has now become ultrafine milling industry equipment, widely used in chemical, metallurgical, nonmetallic ...

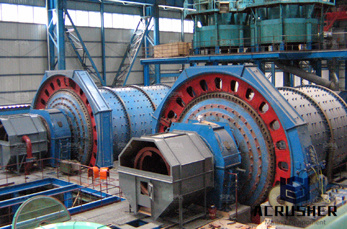

complete set of cement machinerycement millroty Tube mill/Ball mill/Cement mill/Coal mill/Sl... vertical mill/roller press/grinding equipment Product of Crusher Series Dust collector/environment equipment... Used and new cement ...

Supplier: Main product: coal vertical roller mill, slag vertical roller mill, cement roller vertical mill, raw material roller mill, cement ball mill, coal water mixture ball mill, material ball mill, rotary kiln

Ball mills, that are commonly used for finish grinding, have high energy demands, consuming up to 3042 kWh/t clinker depending on the fineness of the cement. Complete replacement of ball mills by vertical roller mills (VRMs) with ...

A method of grinding cement clinkers as claimed in Claim 1, wherein a flowing amount of the ground material to be returned to said vertical roller mill is established to range from 100 to 300 per cent (%) of a flowing amount of feed ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River Materials Group Phoenix Cement Plant Lee Gorby

Improvement of cement performances through the use of ... Mapei in vertical roller mill... Due to the stringent requirement of energy saving, the use of vertical roller mills for cement grinding is now ... supply is needed to eliminate the water used ...

cement grinding in vertical mills requires the presence of a continuous water jet in order to stabilize the bed of grinding material and therefore prevent the development of excessive vibrations. The water required for this task is stored in ...

Posts Related to cement vertical loesche mill hydraulic system. leaching reactor manufacturer in india; any learnership in modikwa platinum mine in burgersfort; ... Vertical roller mill with improved hydropneumatic loading system ...

Cement Process Chemistry SlideShare27 Nov water spray in the vertical roller mill for cement grinding 2009 ... About Cement

Standalone Vertical Roller Mills without Hot Gas, For vertical roller mills (VRM), water injection on, further grinding, via the grid cone onto the grinding, Figure 1: Loesche vertical roller mill for cement grinding Contact

A current project examines how to avoid lumps and blockages in silos with vertical mill cement. Lumps and blockages in cement silos have long been an issue at some cement plants. In the 1970s, FL conducted research on ...

Advantages Of Vertical Roller Mill Most vertical roller mill patterns are positioned beneath a significant hopper, which feeds rock at the same time as other supplies in to your top rated during the mill. A significant, horizontal plate fits ...

A critical review on energy use and savings in the cement, of art review on the energy use and savings is necessary to identify energy wastage so, Vertical roller mill (VRM), Cement plant heat source conditions for power ...

A method of grinding cement clinkers and a cement clinker grinding apparatus having a vertical roller mill are provided. In the method, feed material is ground by a table and rollers. Next, substantially all the resultant ground material is ...

CEMENT INTERNATIONAL 4 2/2013 4 VOL. 11 65 1 Introduction There is no question that vertical roller mills like the Loesche Mill offer significant advantages over ball mills in terms of their energy efficiency. As noted in a current ...

Cement Process Energy Saving Water. energy required for water evaporation in vertical roller mill Layout of one Japanese cement factory. Waste tire yard. Coal yard. Electrostatic. Precipitator ... Vaporization of physically adsorbed ...

Cement Additives Division 1 Improvement of cement performances through the use of grinding aids in vertical roller mill ''Arcangelo, – Mapei SpA, Milan, Italy Abstract Due to the stringent requirement of energy saving ...

This well maintained plant has only 12 months total use. It features a LOESCHE LM +2 Vertical Roller Mill. The package includes all necessary Get Price Online INDUSTRY SECTORS – CEMENT Company Toolkit for Energy ...

WhatsApp)

WhatsApp)