WhatsApp)

WhatsApp)

Cement Kiln Flue Gas Recovery Scrubber project, ... of the Cement Kiln Flue Gas Recovery Scrubber project in CCT Round II, ... wet process and dry process, ...

Chapter 1 Introduction to Cement Production. Audit Procedures for Cement Production Tax ... The wet or dry mix is fed into the kiln, which is one of the largest ...

May 04, 2017· How to Cure Concrete. ... has to be kept wet and if they do dry out they actually aid in sucking ... on top of the slab to stop the evaporation process.

This article will take a closer look at both wet cast and dry cast concrete ... a mixture of cement, ... This "Dry Process" allows you to use one form and ...

THE MANUFACTURING PROCESS Portland cement is made by heating raw materials rich in oxides of silicon, ... the dry process (used by Golden Bay) and the wet process ...

Oct 29, 2012· These are two different processes of manufacturing wet process minerals are wet ground (by adding water) to form a .

Portland Cement . Cement: ... Comparison between wet and dry process Wet process Dry process 1 Moisture content of the slurry is 3550%

How cement is made and ... Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Forms of dry process cement ... Cement Kilns : Dry and semidry process kilns. Kilns Home: ... there was any alternative to making cement "in this country, by a wet ...

Feb 15, 2017· Video embedded· More Details : dry and wet process of cement manufacturing Grinding Mill ... 201289dry and wet process of ...

Cement Kilns: Dry and semidry process kilns. Modern Dry Process Developments. Despite these diversions, the modern dry process in Britain began to develop, somewhat ...

Module: 5 Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 163 Comparison of dry process and wet process Criteria Dry process Wet process

Wet Mix and Dry Mix Concrete: Cost and Quality. ... For storage of cement ... Process Flow of Modular Wet Mix Plant. The process flow of the entire modular wet .

heating the rawmix to sintering temperature (up to 1450 °C) in a cement kiln; grinding the resulting clinker to make cement ... The wet process and the dry process

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments.

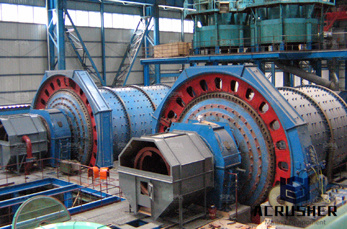

dry and wet process of cement manufacturing. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry.

manufacturing of cement. in ... The three processes of manufacture are known as the wet, dry, and semi dry processes and are so termed when the raw materials are ...

Concrete: When Do You Know It''s Dry ... drying process is "considered" complete and the concrete ... of different thicknesses and watercement ...

The cement kiln Understanding Cement. The wet process has survived for over a century because many raw materials are . However, new cement kilns are of the ''dry ...

When aggregate is mixed together with dry Portland cement and ... The initial natural process of cement hydration with ... concrete where the wet concrete has a ...

Lime Kiln Dust as a Potential Raw Material in Portland Cement ... Each table also indicates whether the cement is operating a dry or wet process and whether the lime ...

SHOTCRETE: WET PROCESS VERSUS DRY PROCESS ... originally called the "cement gun," and the shotcrete ... been involved in both wet and drymix process .

Dry Process Cement Plant, Wholesale Various High Quality Dry Process Cement Plant Products from Global Dry Process Cement Plant Suppliers and Dry Process Cement Plant ...

Intermediate dry process sampling: ... cement production process. According to theory, ... well as inprocess dry (granular/

WhatsApp)

WhatsApp)