WhatsApp)

WhatsApp)

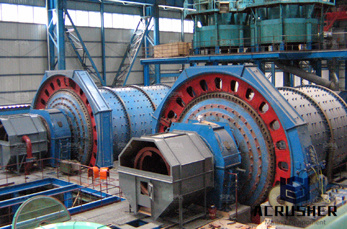

Business Overview CAA Resources Limited We subsequently produce iron ore products through a relatively simple and low cost process which includes ballmilling ...

Nickel Ore Processing. Nickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different.

iron ore processing method ball mill, Chapter 82 Metal Processing and Metal Working Industry. The metal smelting and refining industry processes metal ores and ...

Located near Salt Lake City, Ut, US, Bingham Canyon celebrated its 100th anniversary in June 2003. The Bingham Canyon mine, Copperton concentrator and .

Visitors please visit here to take complete overview and it will give you instructions and some tips on searching and obtaining optin full record data using this ...

® CVXU hydrocyclone, with sizes up to 250mm. Visit this page for a more detailed product overview, specifications and product support information.

iron sand ball mill machinery equipment; ... ball mill for iron ore processing methods. Rod Mill Product Introduction: A grinding equipment with steel rod as medium

Introduction Welcome to the Ticonderoga Branch! This site examines the history of the Delaware Hudson Railroad''s branch lines to Baldwin Dock and ...

Trucks from the mine tip directly into a 400t capacity ROM dump hopper. A primary gyratory crusher crushes the ROM ore from a nominal top size of 1,500mm to less than ...

Process. Material input. Air emissions. Process wastes. Other wastes . Lead sintering. Lead ore, iron, silica, limestone flux, coke, soda, ash, pyrite, zinc, caustic ...

In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores.

Iron is a chemical element with symbol Fe (from Latin: ferrum) and atomic number 26. It is a metal in the first transition series. It is by mass the most common ...

The process of extracting copper from copper ore varies according to the type of ore and the desired purity of the final product. Each process ...

Iron ore Wikipedia, the free encyclopedia. Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or ...

Classification Minerals Spiral Classifier with tank design for optimal performance The Minerals Spiral Classifiers are designed to

Gold is often found associated with the mineral quartz. It is sometimes associated with other minerals as well, including iron and manganese oxides, calcite ...

Heat Treating/Cryogenic Processing of Knife Blade Steels Improving the Service Properties of High Alloy Blade Steels Welcome to the best page on heat treating and ...

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals ...

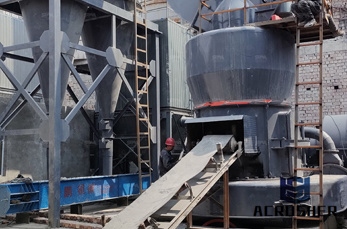

Crushing plant and grinding mill are widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on.

1. Introduction. Sometimes, the usual methods of processing are not able to completely remove the phosphorus present in some types of iron ore when trying to make the ...

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

The processing method selected and other processing assumptions, including the recovery factors applied: The processing plant design criteria are based on:

® CMW Series Coarse Washers clean coarse material containing very water soluble slits and soft clay. Access full specifications and support details.

Ball Mill – A steel ... minerals in an ore. BioLeaching – A processing method that uses ... Mill – A processing plant which treats ore for the purpose ...

WhatsApp)

WhatsApp)