WhatsApp)

WhatsApp)

The relationship between the comminution energy and the product size obtained for a ... Bond ball mill test results and composition of the LIMS product

Figure 1 – Vertimill features (, 2005) The fundamentals of fine and ultrafine grinding in a stirred ball mill were detailed by Herbst and

Enormous quantities of energy are consumed in size reduction ... limestone material to a smaller size using a ball mill and to ... efficiency, the energy input is ...

Ball mill definition of ball mill by The Free Dictionary. ... ball mill optimization, efficiency. ... ball mill; ball mouse;

Choosing a SAG Mill To Achieve Design Performance ... With good definition for the design power level settled the next ... SAG efficiency in the commercial mill.

An Overview Of Lime Slaking And ... factors that affect efficiency and performance of lime slaking systems. ... Ball mill slakers are an adaptation of ball mills, ...

DESIGN OPTIMIZATION OF HIGH ENERGY BALL MILLS BY DISCRETE EVENT SIMULATION Roland Reichardt and Wolfgang Wiechert Department of Simulation .

FM 306: SIZE REDUCTION AND SIEVING OBJECTIVE •To grind the given limestone material to a smaller size using a ball mill and to obtain the size distribution of the ...

fgd limestone ball mill efficiency ... Particle Size Efficiency definition, ... steel media for use in lime slaking mill. slaking efficiency particle size ...

Ball Mill Online Estimation of Inmill Slurry Density. Magotteaux. Effect of Slurry Density on Load Dynamic and Milling Performances in an Iron Ore. Ball Mill .

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Plant performance improvements ... to measure and increase ball milling circuit efficiency. ... ball mill size distribution data showed that the CSE at 106

The harder the media the better the grinding efficiency and consequently, ... The theoretical critical speed of a ball mill is the speed at which the centrifugal ...

control schema for the primary ROM ball mill discussed in more detail below. ... Milling efficiency in this case was defined as the amount

MEDIA MILLING FOR CHEMICAL APPLICATIONS ... such as ball mills, ... The graph shows the increased efficiency of the DMQ mill vs. the Deltamill grinding calcined clay

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

Effect of circulating load and classification efficiency on HPGR and ball mill capacity Alex Jankovic1, Walter Valery1, Birol Sönmez2 and Renato Oliveira2

IsaMill Ultrafine Grinding for a Sulphide ... Fine grinding mills have improved in design and efficiency in ... microns in a conventional ball mill, were in ...

Ball Mills. Grinding Mill Surging. The phenomenon of "surging" in a mill is a subject upon which very little has been written; ...

A typical processing line at a mine might consist of a crusher followed by a SAG mill followed by a ball mill. ... bypass the crusher itself, thus improving efficiency.

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ ... Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and

High Energy Ball Mill having following specifications:1. Feed material: hard, brittle, soft to medium hard Max. feed size: 8 mm3. Final fineness: =1 micron4.

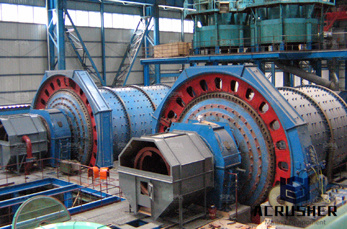

A ball mill is a grinding device that is used to turn material into fine powder. Ball mills are cylindrical in shape, and are often the grinder of choice when it ...

WhatsApp)

WhatsApp)