WhatsApp)

WhatsApp)

"Firing" in cement industry parlance is the supply of heat to a kiln by use of a burning fuel. Throughout the early history of the industry, fuel was added to static ...

speed control of rotary kiln. ... burner fuel and for sensors to control the speed of rotary kiln could help to ... kiln fuel control process in cement ...

Kiln Speed. Hey; can anyone tell me how can i calculate the optimum speed for kiln feed? what i mean is, when our kiln capacity is 143 t/h the kiln speed is rpm ...

Rotary kilns for cement plants. ... modern cement plant. The 2base rotary kiln is a statically determined beam ... The kiln rotational speed is designed for rpm ...

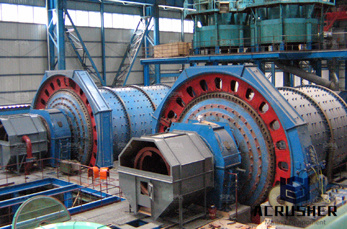

Cement Kiln Model: Φ2 ... Cement rotary kiln adopts adjustable speed driving with high efficient and low ... accurate speed control and easy control the calcination ...

A kiln (/ k ɪ l n / or / k ɪ l /, originally pronounced "kill", with the "n" silent) is a thermally insulated chamber, a type of oven, that produces temperatures ...

metals cranes mining testing oil gas solar inverters utilities cement Drive Solutions for the Global Cement ... speed control, ... control. The cement kiln drive ...

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

HC900 Cement Plant Kiln Control Application Brief Industry: Cement ... can invoke forced kiln speed control that continuously increases kiln speed while all

Solutions for the Preheater Tower Inlet Chamber Kiln Inlet Due to the fast development in the cement industry, furnace builders have to consider new construction

Additives The raw ingredients of portland cement are ime, si ica, alumina and iron Lime is obtained from ca careous rock deposits and industrial alkali waste ...

In cement making line, when the rotary kilns need cooling and temperature rise, its running speed needs to be slowed down. Here we will give a detailed anal

when our kiln capacity is 143 t/h the kiln speed is rpm. how can i calculate the kiln speed for 130t/h ... Cement Factory Quality Control; White Cement ...

Cement Kiln Speed and Torque Control Variable speed drives are used to control the rotational speed of cement kilns. In addition to enhanced process ...

Table 2: Composition of portland cement with chemical composition and weight percent. When water is added to cement, each of the compounds undergoes hydration and ...

REFRACTORY SOLUTIONS FOR CEMENT PLANTS INNOVATIVE REFRACTORY SOLUTIONS FOR THE CEMENT INDUSTRIES Calderys India Refractories Ltd. We offer a full range of ...

With Siemens drive systems you have full control of the speed of your kiln improve the performance and maximize your profits on the output of your kiln system.

Wood drying (also seasoning lumber or wood seasoning) reduces the moisture content of wood before its use. When the drying is done in a kiln, the product is known as ...

Glossary of Commercial Construction Industry Terminology© A B C D E F G H I J K L M N O P Q R S T U V W X Y Z. A. AAMA – Architectural Aluminum Manufacturer''s ...

Commercial Food and Cheese Chopping and Cutting Equipment. Schier Company Inc. has a wide variety of cutters available including grinders, shredders, flakers and ...

Europe''s most modern cement kiln, at Castle Cement''s Padeswood works in north Wales, is being speed controlled by two, 300 kW ABB industrial drives.

• What is Cement? • History • Overview of the Cement ... Kiln Speed, Gas Flow ... Cement Kilns Excellent Environment

Inner Structure and Advantages of Cement Kiln. As a kind of rotary kiln, cement kiln is mainly used for calcining ... reliable operation and easy control of the ...

Get your weekly DIY fix with our customized newsletter. Thanks! You''ve been added to our list. Good stuff is on its way!

WhatsApp)

WhatsApp)